Steel, Fulfilling a Positive Role in World’s Sustainable Future

Steel has a crucial role in building a strong world. It is this metal that makes much of our life moving forward. From its invention, to the most current technologies and uses, it won’t be fallacious saying that the world won’t have been the same without this revolutionary material. Steel not just hasn’t changed millions of lives, it has been contributing immensely to the cause of the world. Steel propels the world's economy and nations’ growth relies heavily on it.

The industry has rapidly moved on from being the world’s growth engine to a sustainable growth proponent. Let’s see how the industry contribute to the cause:

Contributing to the circular economy

The circular economy (CE) model always offered new chances of innovation and integration. When compared to other linear business models, where products are manufactured from raw materials, used and then discarded, the steel industry’s circular business models are more sustainable where products or parts are restored, repaired, re-used, returned and recycled effectively.This circular economy concept fundamentally is the bottom line concept of sustainability, which focuses on the interplay between environmental, social and economic factors. They are based on a life cycle approach. In a well-structured circular economy, steel has noteworthy benefits over competing materials. That said, continuing to fulfil a positive role in our sustainable future comes with some major challenges.

Recyclability

Steel is a major constituent material that goes into making of a wide range of market applications and products that we see in the market, such as in the automotive, construction and packaging sectors. Thanks to Innovative technology developments and synergies with other industries, steel is being continually recycled without loss of properties or performance is itself a great advantage. Steel scrap is 100% recyclable, and it can be reused any number of times without damage or harm in quality. It has brought the steel industry ever closer to its goal of zero waste to landfill. 40% of the world’s steel is made from scrap steel, and on average new steel products contain 37% recycled steel. Any grade of steel can be recycled to top quality new metal, without affecting the quality of materials as steel is recycled repeatedly.

Use of by-products

Over the past many years, use of the steel industry’s co-products has increased considerably. Steel industry co-products like blast furnace slag, steelmaking slag, process gases, dust and sludge are being readily used as substitute for clinker in cement-making, aggregates in road construction, soil improvement, heat and electricity production, or it could be also used as tar, ammonia, phenol, sulphuric acid and naphthalene for the chemical industry. Not only do they contribute to the conservation of resources, it saves natural resources and reduces environmental impact.

Energy efficiency

Steel industry’s improved energy efficiency has reduced the cost of production, thanks to the technological prowess that has gone into production in the last 20 years. The energy generated from waste is also captured and used effectively. A recent study shows that the average energy intensity for steel production is 20 GJ/tonne crude steel, with a potential progress of 15-20.

Low carbon future

The use of steel scrap reduces CO2 emissions significantly. Working closely with its customers and optimising the design and use of steel is a key contribution in this regard. As a part of the Climate Action initiative, Worldsteel has been encouraging all its members, including the non-member companies, to participate in its climate action programme, which is the collection and reporting of CO2 emissions plant-by-plant.

Lifecycle approach

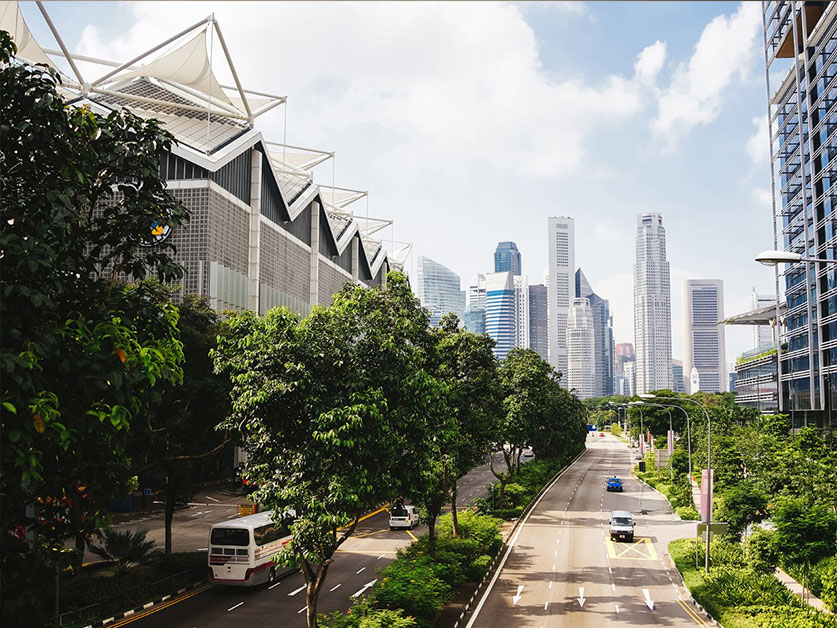

Lifecycle thinking is key to every aspect of sustainability where environmental, social and economic impact of products is taken into account while. The industry is steadfast in using new-generation steels in lighter and stronger products. The industry is further looking for good examples around the world where steel is more predominantly used in infrastructure and large public buildings as well as offices and residential buildings and where these provide better energy efficiency and climate resilience.

For a greener tomorrow

The global steel industry is working together on a number of path-breaking initiatives in technology development and sharing programmes where all necessary data are shared on subjects impacting the steel industry. This directly contributes to improving the environmental performance of steel plants around the globe especially in air quality, by-products, energy use, maintenance and reliability, raw materials, and water management. The WorldAutoSteel is steadily working on a programme for optimising steel use in future vehicles, including electric and hybrid.Striking the right balance between the rising demand for steel and efforts of meeting the global need for sustainability is indeed a tough ask. But with all these efforts we can rest assured that the world is safe and the efforts are definitely in sync with the changing needs of the Industry and the people at large.